Ultra-high-performance compounds for demanding applications

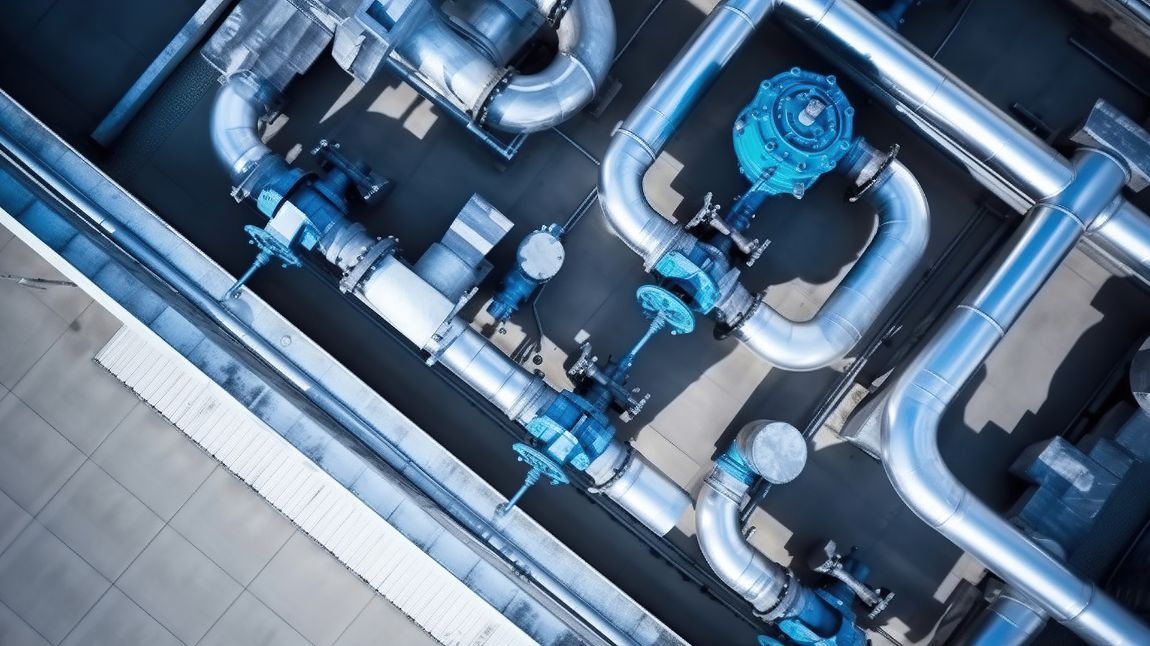

Process Industry

Manufacturers of sealing solutions and engineering plastics components for the process industry have to deal with an increasingly challenging environment: Difficult technical requirements and the need for sealing and engineering plastics solutions to withstand challenging conditions like SIP (sterilization in place) & CIP (cleaning in place) processes. Also, overall growing markets requiring more and more industry- and country-specific approvals, as well as a growing concern for health especially in the pharma and food & beverages industry are just some of the other issues that need to be addressed. And of course, standardization is also an important concern, so a solution fit for “everything” and approved for use “everywhere” has optimal market perspectives. Angst+Pfister can offer this!

The right product at the right time

For over half a century, Angst+Pfister has served the leading manufacturers and operators within the processing industry by supplying them with comprehensive high-performance sealing technology and engineering plastics solutions for a large range of applications like pumps, valves, gauges, sensors etc. Offering everything from one source our customers benefit from customized engineering and onsite consulting, a very high level of international certification and the very high availability of standard materials and products.

Furthermore you can count on our extensive global production platform. Our Global Logistics Centre offers more than 140,000 items available in stock, and with supply chain management solutions like just-in-time or kanban we can serve your customer-specific requirements with the right quality standards and the best price at all times.

Learn more about our group-wide supply chain capabilities!

Our high-performance elastomers

With PERTEC® Angst+Pfister also offers an own range of high-performance elastomers featuring:

• Broad chemical resistance over a wide range of aggressive liquids

• Very good ozone-, weather-, age- and oxygen-resistance, also against mineral oils and greases

• Low gas permeability

• Temperature resistance from -60°C up to +200°C

• Almost all important approvals for the chemical, oil, gas, food and water industries

Here, compound production and a high reliability during the whole manufacturing process are crucial aspects. We offer state-of-the-art moulding, de-flashing, grinding, post curing and visual inspection processes in our in-house production.

Learn more about the elastomeric compounds we offer!

Approvals and conformities

Angst+Pfister is not only an expert when it comes to understanding the regulatory jungle and incorporating mechanical and chemical requirements into its components, but is also a member of the European Hygienic Engineering & Design Group (EHEDG), a non-governmental organization devoted to the advancement of hygienic design and food engineering.

Especially in the area of sealing solutions, we always strive to meet the highest hygienic design standards in order to enable safe food production, to minimize hygienic risks and to comply with the growing number of dietary constraints and changing consumption habits.

Our services

Our customers include

Contact Form

We make it work!

Just contact us and We will get back to you as quickly as possible!

Stay up-to-date!

Sign up for our newsletter today and receive our newest updates on products and latest industry trends!