Comprehensive Solutions for Diverse Hose Needs

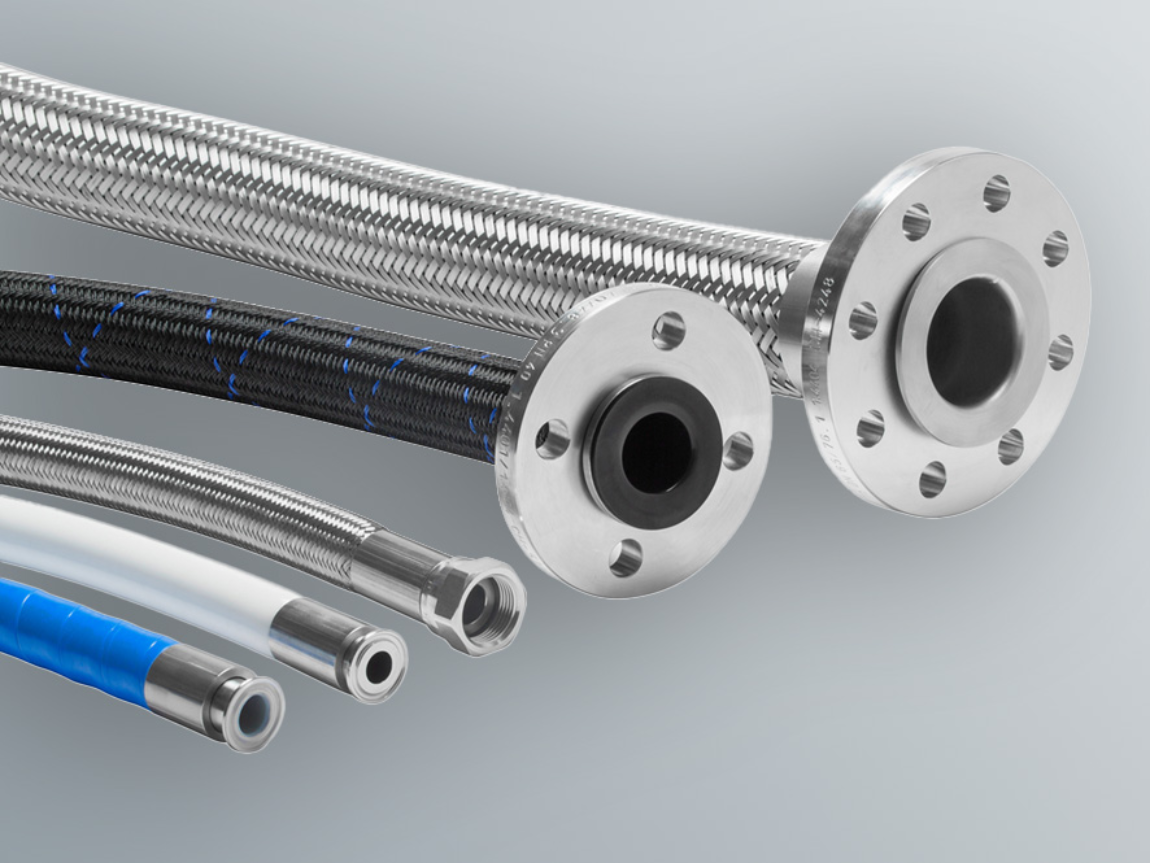

Single-Layer Hoses

Discover our single-ply hoses designed for superior durability and performance in various industrial applications. We offer two types of these hoses, FLEXILON® thermoplastic hoses and single-ply elastomer hoses that provide exceptional flexibility and abrasion resistance.

Made of thermoplastics, FLEXILON® hoses serve various purposes, including pneumatic applications and the transport of chemicals. They are available in various dimensions and transparent colours and comply with various standards applicable to the food sector. Customisation is available on request, allowing flexible adaptation to specific requirements such as moulded parts.

Our single-layer tubing is designed for flexible use in various industries and fulfils approvals such as USP Cl. VI, FDA or NSF 51 etc., thus ensuring suitability for applications in the pharmaceutical and food industries.

Multi-Layer Hoses

Our multilayer hoses cover a wide range of applications, from the chemical and pharmaceutical industries to the steam, food and beverage industries. Rigorous testing ensures compliance with industry standards and regulations, while a range of fittings ensures compatibility and functionality.

Our range includes hoses, matching fittings and pre-assembled hose assemblies for the main industries:

- Food and beverage industry

- Drinking water supply

- Pharmaceutical and medical technology

- Machinery industry

- Railway

High-Performance Hose Lines

Our high-performance hose lines include the TETRAFLEX® and TETRAWELL® hose lines. They are characterised by a very wide temperature range [from -70°C to +260°C (depending on pressure reinforcement and outer jacket)], by positive and negative operating pressures (THROUGH over- and under-operating pressure), depending on the hose construction.

All TETRAFLEX® hose lines have a smooth inner layer that is suitable for both high-pressure and high-flow applications. Depending on requirements, TETRAFLEX® hose lines are available in various designs, including those with an additional stainless steel spiral for vacuum applications or tight installations (small space requirements). The high-performance TETRAFLEX® hose lines with FDA-compliant silicone sheathing are perfect for the pharmaceutical and food industries. Other versions with an antistatic or electrically conductive PTFE inner layer are also available for explosion protection zones.

TETRAWELL® offers flexible PTFE hose lines in flat or deep corrugated versions, each of which fulfils specific pressure and flexibility requirements. The latter are characterised by flexibility and bending behaviour, while flat corrugated hoses are ideal for lower pressure losses and higher pressure values. Stainless steel spirals are also available for higher vacuum loads. Choose from a wide range of materials and designs for both braiding and brazing.

Seamless Solutions

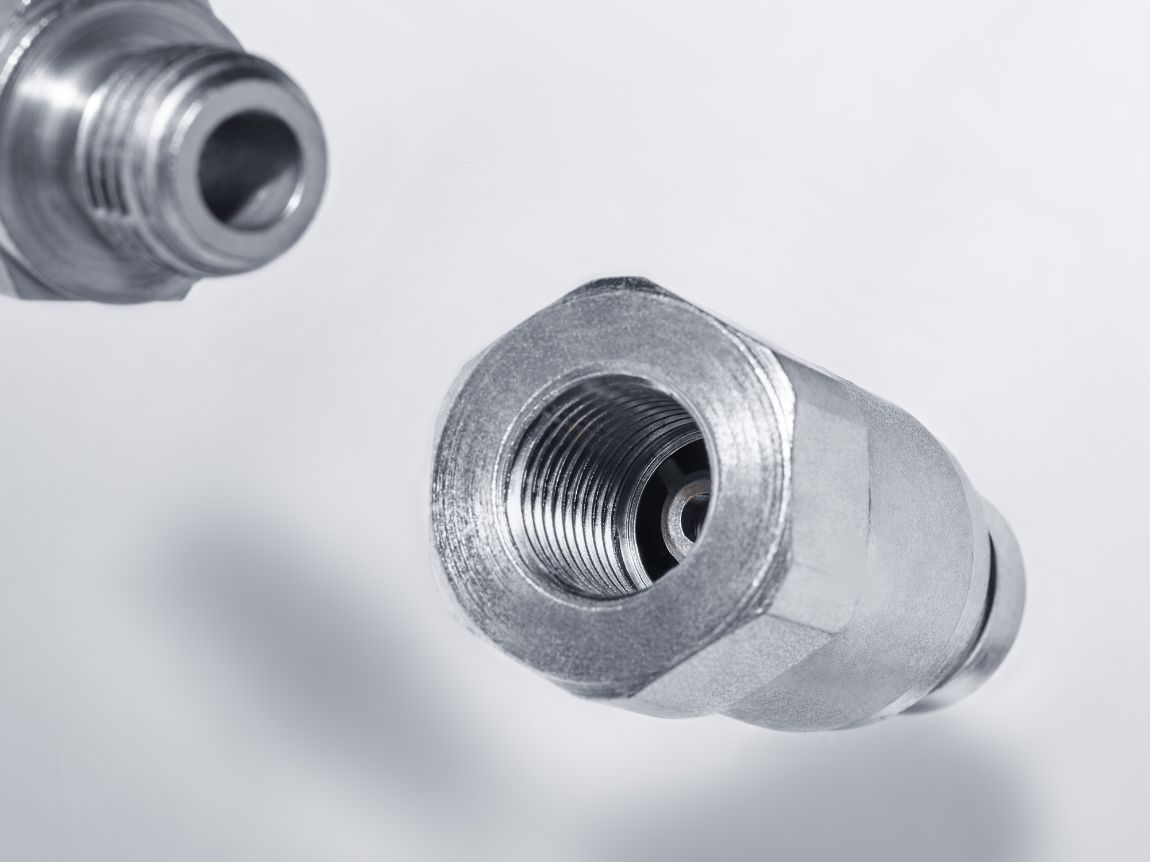

Fittings and Fasteners

Our meticulously designed fittings ensure seamless integration with our hoses while meeting industry standards for safety and efficiency. Available in materials like brass, stainless steel, and plastics, we offer a wide range of standard fittings and can customize as needed such as:

- Milk pipe fitting

- TriClamp

- DIN / ASME flange

- Lever arm fitting

- Hydraulic fitting

- Fastening element (press fitting, clamping jaws)

- Adapter

The Vital Role

Compensators in Piping Systems

Compensators play a crucial role in engineering solutions, acting as flexible elements composed of an elastic bellow and a connection element like a flange. They serve to compensate for thermal expansions, mechanical vibrations, acoustic vibrations, and tensions within piping systems, fittings, pumps, and devices. Additionally, compensators provide noise insulation.

Commonly found in heating systems, water pipes, power plants, and the chemical industry, compensators are tailored to match various fluids encountered, such as drinking water, oil, or food-grade substances. Proper installation is paramount to ensure optimal functionality, with different length limiters absorbing reaction forces, negative pressure forces, and accommodating freedom of movement and adjustment forces.

Metal and rubber expansion joints have a common purpose - to compensate for thermal or mechanical changes that cannot be absorbed within the system. Installation considerations, including medium, pressure, temperature, location and type of movement, are critical to prevent system damage and failure. Our specialists are ready to select or design the ideal expansion joint solution ----> replaced by "design" that is tailored to your specific requirements.

Which industry are you in?

Our Key Industries we serve for Fluid Handling Solutions

Let’s Talk about your Project!

Request a Free Consultation and Find a Perfect Solution Customized for you.

Based on our assortment we create and develop an individual solution for your application – or we even develop from scratch a high-performance part for your product to ensure quality & safety. For expert advice and customized solutions tailored to your specific needs, Angst+Pfister service offerings are your go-to resource in fluid handling solutions.

Let's talk!