At the core of every breakthrough in healthcare lies more than just medical expertise – it’s the precision, safety, and innovation embedded in Pharma and MedTech engineering that elevate patient care. In today’s industry, ensuring performance and reliability means developing high-quality, biocompatible materials and components that meet the strictest global regulatory standards.

With our advanced solutions we meet safety requirements, as well as with certifications in place to support critical applications. From fluid handling systems to sealing solutions, we prioritize compliance, hygiene, and durability, providing components that withstand sterilization, high temperatures, and aggressive cleaning agents.

Our commitment to safety and quality enables us to offer trusted solutions that integrate seamlessly into medical and pharmaceutical applications. Whether serving equipment manufacturers or healthcare providers, we deliver the essential components that drive innovation and reliability in healthcare – every day.

Main Challenges in the Pharma & MedTech Industry

Material Compatibility and Regulation Compliance

Seals must be crafted from materials compatible with various chemicals and biological substances, including aggressive solvents and high-temperature sterilization processes exceeding 121°C. Meeting stringent regulations, such as FDA and USP standards, is essential; non-compliance can result in product recalls and penalties, highlighting the importance of using reliable, certified materials in seal manufacturing.

Avoiding contamination

In the Pharma and Medical industry all components in contact with products are inert and free from contaminants like phthalates, plus being easy to clean in the process ensuring no risk to product quality. Strict hygiene measure required such as CIP and SIP can also be rough in the material used in productions, for instance seal.

.jpg)

Avoiding production stand still

Production standstills in the Pharma and Medical Industry are often caused by equipment failures, poor maintenance, or mechanical breakdowns. Other causes include supply chain disruptions, ingredient shortages, and manual errors. Hygiene issues or regulatory non-compliance can lead to temporary shutdowns, while inefficient process management and lack of automation also contribute to downtime, impacting overall productivity and product quality

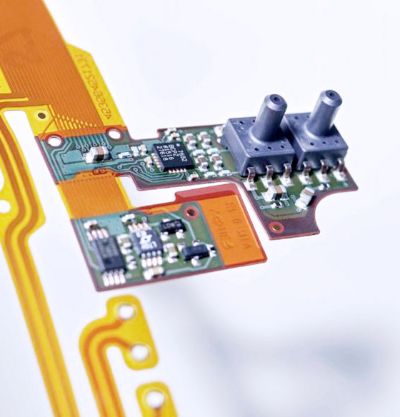

Vibration Control in MedTech devises

Medical devices like imaging and diagnostic equipment rely on vibration control solutions to ensure accuracy, long-term reliability, and patient safety. Wear-resistant, vibration-dampening materials are essential, meeting strict safety standards to prevent degradation and support optimal device performance and patient comfort.

The Right Choice from the Start - Angst+Pfister's Solution for the Pharma & MedTech Industry

How Angst+Pfister’s Solutions Are Being Applied:

- FDA and USP-Approved Elastomers: Materials approved by FDA and USP to ensure compliance and safety across a range of pharmaceutical and MedTech applications.

- Sterilization-Resistant Seals: Robust seals designed to withstand sterilization, high temperatures, and pressure variations, ensuring integrity in critical medical devices.

- Customized Seals and Modelde Parts for Medical Devices: Customized seals developed specifically for medical devices, providing optimal performance and reducing the risk of system failure.

- Durable, Cleaning-Resistant Seals and Engineering Plastcs: Materials resistant to aggressive cleaning agents and sterilization processes, designed to maintain durability and meet stringent requirements in MedTech and pharmaceutical applications.

Customer Benefits:

- Enhanced Durability: Seals and components are engineered to resist high temperatures, pressure changes, and aggressive cleaning agents, reducing the need for frequent replacements.

- Precision and Accuracy: Vibration control solutions provide reliable, wear-resistant performance that supports accurate diagnostic and imaging equipment, extending device lifespan.

- Customization for Specialized Applications: Tailored sealing solutions are available for specific devices, optimizing performance, minimizing failure risk, and meeting the unique needs of MedTech equipment.

- Reliability Under Harsh Conditions: Our materials are specifically designed to withstand exposure to challenging sterilization processes, ensuring long-lasting and dependable performance.

Boost Your Performance With Our Solutions

.jpg)

Innovative elastomers determine the future of sealing technology.

A comprehensive o-ring- and molded part assortment

Radial shaft seals and axial shaft seals for applications with rotational motion

At Angst+Pfister, we stay ahead of the curve in Engineering Plastics Technology. We offer a comprehensive range of services for practically every applica ...

Related Downloads

Let’s Talk about Your Project!

Request a Free Consultation and Find a Perfect Solution Customized for you.

Based on our assortment we create and develop an individual solution for your application – or we even develop from scratch a high-performance part for your product to ensure quality & safety. For expert advice and customized solutions tailored to your specific needs,

Let's talk!

We make it work!

Just contact us and We will get back to you as quickly as possible!

Stay up-to-date!

Sign up for our newsletter today and receive our newest updates on products and latest industry trends!