At the core of every reliable rail journey lies more than just advanced trains—it's the engineering precision, resilience, and innovation in railway components that drive safety and comfort. In today’s rail industry, achieving high-performance materials and solutions means building components that can withstand intense vibration, extreme temperatures, and strict safety regulations.

The expertise of Angst and Pfister in high-quality and compliant components ensures seamless integration across rail systems, from vibration control to to EN45545 compliant components. By prioritizing global certifications and environmental standards, we deliver components that enhance passenger comfort, reduce noise, and improve durability. Whether optimizing for passenger or cargo transport, our solutions support reliable, efficient, and safe rail operations worldwide.

Main Challenges in the Railway Industry

Vibration Control and Noise Reduction

Vibration control and noise reduction in railway systems are critical for enhancing passenger comfort and minimizing environmental noise pollution. High-speed trains generate substantial vibration and noise from track interactions and mechanical systems, necessitating engineering solutions like anti-vibration mounts, shock absorbers, and dampers to improve ride quality, protect components, and reduce external noise impact.

Safety on Board and Reliability

Rail transport components require high-temperature and fire-resistant materials to ensure durability and safety in passenger and cargo systems. Components like seals, gaskets, and hoses use advanced elastomers to withstand engine heat, meet fire safety standards, and aid in electrical heat dissipation, protecting both passengers and cargo while ensuring system reliability under thermal stress.

Longevity and Maintenance Minimization

Railway components must endure heavy use, long service intervals, and minimal maintenance to ensure efficient, cost-effective operations. Seals, gaskets, and vibration controls require durability against wear and aging, while ease of installation and quick replacement are essential in critical systems, reducing downtime and maintaining reliability in high-speed and freight trains.

Ensuring Leak-Free Performance and Reliability

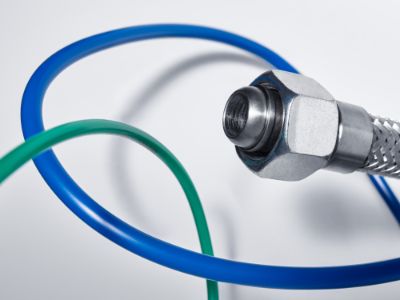

Railway braking, suspension, and coolant systems demand highly durable seals and hoses to ensure safety and reliability. Hydraulic and pneumatic components require leak-free operation under high pressure, while cooling systems depend on temperature-resistant seals to manage engine and electrical system heat effectively. Robust sealing solutions prevent leaks, withstand vibration, and protect against corrosion, guaranteeing efficient and safe railway operations.

The Right Choice from the Start - Angst+Pfister's Solution for the Railway Industry

How Angst+Pfister’s Solutions Are Being Applied:

- Antivibration Technology: Our anti-vibration mounts, shock absorbers, and dampers significantly reduce noise and vibrations, enhancing passenger comfort and protecting critical components.

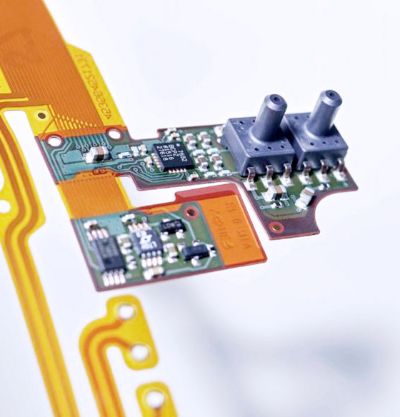

- Thermal Management with Elastomers: Advanced elastomers manage heat and support electrical heat dissipation, protecting both passengers and cargo while ensuring consistent performance under thermal stress.

- Sealing Solutions: Our advanced sealing technologies are used for train doors, windows, and hatches, providing reliable seals that accommodate dynamic movement and ensure smooth operation in sliding and retractable systems.

- Suspension and Bogie Systems with Sealing: Our robust seals are engineered to withstand high vibration and dynamic loads, enhancing durability and performance in demanding rail environments.

- Extensive Testing: We conduct torough pre-testing to validate materials against industry standards, ensuring every solution meets the demands of railway applications.

- Hose Line Safety and Reliability with Fluid Handling Technology: We supply hose line components that meet all relevant regulations, standards, and approvals, guaranteeing their availability and compliance at all times. Our hoses are engineered not only for resistance to conveyed media but also for durability against environmental influences, helping to reduce railway shutdowns.

- Space-Efficient Shaped Parts with Sealing and Fluid Hanlding Solutions: Limited space in railway installations can lead to hose kinking, compromising function and safety and potentially incurring high costs. Our precisely engineered shaped parts provide a reliable, safe solution to prevent kinking and ensure dependable performance.

Customer Benefits:

- Enhanced Passenger Comfort: Our vibration control and noise reduction solutions improve ride quality, ensuring a more pleasant experience for passengers.

- Regulatory Compliance: We provide materials that meet stringent fire safety standards, including EN45545, ensuring compliance and safety for all railway components.

- Durability Under Stress: Our fire-protected elastomers and high-quality hoses withstand extreme temperatures, harsh environmental conditions, and stringent operational demands, guaranteeing reliable performance in challenging railway settings.

- Efficient Material Selection: Our thorough pre-testing and extensive materials database facilitate a more straightforward development process, allowing for prompt and effective selection of materials that align with customer requirements.

- Environmental Responsibility: By prioritizing energy efficiency throughout both production and operational use, our solutions support eco-friendly practices, helping rail operators minimize environmental impact.

Proven Success in Motion - Our Customer Stories

Angst+Pfister collaborated with South Korea's Dawonsys on antivibration components.

At the forefront of industry standards

We prioritize safety and innovation for the railway industry. Our engineering team develops patented products annually, focusing on antivibration, sealing, and hose line systems. Our Angst+Pfister solutions meet the highest industry benchmarks, complying with rigorous standards like DIN EN45545 or other nation-specific Smoke and Fire Standards. Angst+Pfister actively engages in Standards Committees to stay ahead of evolving requirements. Additionally, our production facilities hold the prestigious IRIS Certification, ensuring their commitment to quality and compliance. Trust Angst and Pfister for cutting-edge railway solutions.

Quality testing

We test and certify our innovations in laboratories which are recognized globally for their expertise. Furthermore, we are proud of our Quality Management process, making Angst+Pfister a market leader in product conformity within the railway industry.

Our customers benefit from these competitive advantages through a solid partnership. We are convinced that co-design projects are the best solutions for reduced time-to-market.

Angst Pfister Advanced Technical Solutions Inc. R&D Test laboratory is accredited by TÜRKAK with the accreditation number AB-1769-T for TS EN ISO/IEC 17025:2017 Standard and It has the first and only Test laboratory in Turkey accredited according to the scope of EN 13913.

Fill in the Data Protection for here

Boost Your Performance With Our Solutions

.jpg)

Innovative elastomers determine the future of sealing technology.

A comprehensive o-ring- and molded part assortment

Radial shaft seals and axial shaft seals for applications with rotational motion

Discover tailored solutions and efficient components for diverse fluid applications, backed by expertise and a commitment to prompt delivery

Let’s talk about your project!

Request a free consultation and find a perfect solution customized for you.

Based on our assortment we create and develop an individual solution for your application – or we even develop from scratch a high-performance part for your product to ensure quality & safety. For expert advice and customized solutions tailored to your specific needs, Angst+Pfister service offerings are your go-to resource for your next projects!

Let's talk!

Related Downloads

We make it work!

Just contact us and We will get back to you as quickly as possible!

Stay up-to-date!

Sign up for our newsletter today and receive our newest updates on products and latest industry trends!