At the heart of every exceptional coffee experience lies more than just quality beans – it's the precision, reliability, and innovation in coffee machine engineering that make all the difference. In today’s coffee machine industry, meeting the demands for performance and durability requires advanced high-quality seals and fluid handling technology that can withstand intense operational pressure.

Our expertise in crafting components that meet stringent industry standards ensures that every cup brewed by our machines reflects superior quality. We prioritize the latest certifications and regulatory compliance, delivering fluid handling systems that are hygienic, efficient, and sustainable. From maintaining perfect water pressure to ensuring thermal stability, our components are designed to seamlessly integrate into coffee machines, enhancing their efficiency and longevity.

With our unwavering commitment to meeting international standards, our seals and fluid systems are rigorously tested to comply with food safety regulations and environmental certifications. Whether you're a machine manufacturer, coffee professional, or café owner, we provide the critical components you need for a flawless brew – every time.

Main Challenges in the Coffee Machine Industry

Ensure Consistent Quality of Taste

Consumers expect every cup of coffee to deliver consistent taste, aroma, and texture. Coffee machine manufacturers must ensure precision in brewing temperature, water pressure, and extraction time, while also using seals that preserve each coffee’s unique aroma, preventing any flavor distortion across different coffee types.

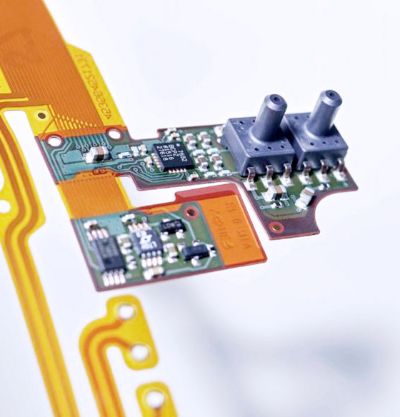

Automatic Assembly in the Production of a Coffee Machine

Due to the large quantities involved, seals in the coffee machines industry are often fitted automatically. It is therefore very important that the gaskets are flat and round so that they can be gripped easily by the automatic assembly machines. Good sliding properties also play an important role so that the gasket is not twisted during assembly.

Durability and High-Temperature Resistance

Consumers often overlook the need for regular maintenance of coffee machine seals, leading to performance issues. Residue buildup, high temperatures, and frequent use strain seals and fluid components, demanding resistance to wear and cleaning agents. Durable, precise seals are essential to prevent costly repairs and ensure efficient operation.

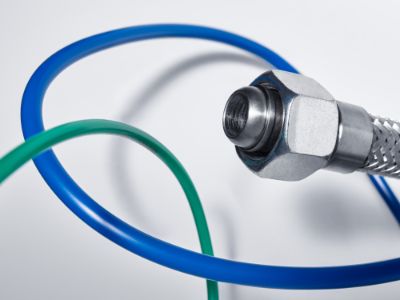

Leak Prevention and Fluid Control

Proper fluid handling is critical to prevent leaks, maintain consistent water pressure, and ensure accurate fluid dosing in coffee machines. Any failure in seals or fluid control mechanisms can lead to machine malfunction or compromised beverage quality. The challenge lies in designing systems that are robust yet flexible enough to perform under varying conditions.

The Right Choice from the Start - Angst+Pfister's Solution for the Coffee Machine Industry

How Angst+Pfister’s Solutions Are Being Applied:

- Global Food Compliance Materials: Recommended materials comply with all global food approvals and meet specific migration limits for the coffee machine sector.

- Customized Seals and Elastomers to keep the coffee quality: Specialized seals designed to prevent aroma diffusion, helping to maintain coffee quality and avoid spoilage that could disrupt production.

- Tempering Processes for Seal and Modeld Parts Integrity: Unique tempering processes minimize deformation, ensuring seal integrity even under high-pressure and high-temperature conditions.

- Antivibration Technology for Friction-Reducing Coatings: Friction-reducing coatings on seals and components promote smooth operation and reduce component wear over time, enhancing durability.

Customer Benefits:

- Global Compliance: All materials meet relevant food safety regulations (e.g., EC 1935/2004, EU 10/2011, FDA standards) and migration limits, ensuring consistent compliance.

- Ensure Quality of Taste: Specialized elastomers like FKM, VMQ, HNBR, and EPDM prevent aroma permeation, preserving product quality by reducing spoilage risks and flavor loss.

- Customized Seal Durability: Tested through FEM simulations, achieve high durability and minimal deformation, even under extreme conditions.

- Enhanced Performance with Surface Coatings: Applied coatings reduce friction, extending the lifespan of components and minimizing maintenance needs.

- Efficient Production with GMP Standards: Angst+Pfister’s GMP-certified manufacturing and machining processes produce high-quality plastic components precisely suited to each application

Proven Success in Motion - Our Customer Stories

Eversys and Angst+Pfister collaborated to develop compact, efficient coffee grinding technology.

Franke and Angst+Pfister co-developed space-saving dampers to reduce coffee machine vibrations.

We solve the complexity of the food regulation jungle

More and more global customers require the industry-specific approvals of all major markets to avoid proliferation of numerous country-specific solutions. Just to mention a few, Angst+Pfister covers all the most important approvals such as EC 1935/2004, EU 10/2011 and GMP 2023/2006 for Europe, FDA CFR 21 and NSF 51 for the USA, GB 9685-2016 for China, Food sanitation Art. no. 233 for Japan, as well GMC/Res no. 03/92 and GMC/Res no. 32/07 for the MERCORSUR area.

Boost Your Performance With Our Solutions

.jpg)

Innovative elastomers determine the future of sealing technology.

A comprehensive o-ring- and molded part assortment

Radial shaft seals and axial shaft seals for applications with rotational motion

Discover tailored solutions and efficient components for diverse fluid applications, backed by expertise and a commitment to prompt delivery

Related Downloads

Let’s Talk about Your Project!

Request a Free Consultation and Find a Perfect Solution Customized for you.

Based on our assortment we create and develop an individual solution for your application – or we even develop from scratch a high-performance part for your product to ensure quality & safety. For expert advice and customized solutions tailored to your specific needs,

Let's talk!

We make it work!

Just contact us and We will get back to you as quickly as possible!

Stay up-to-date!

Sign up for our newsletter today and receive our newest updates on products and latest industry trends!