Leaf Spring Bushings

In motor vehicles, leaf springs are most generally used in the rear suspension hardware. Leaf springs are made by the curving of flat steel bands. It is formed with the tying of a couple of thin leafs with short ones and then the longer ones put on top of one another. With this tying method, it does not break and is forced to be flexible. Every curve of the leaf is called a bend and this bend intensifies from the longer leaf to the shorter leaf. With the curving of the edge of the longest spring a spring eye is formed.

In motor vehicles, leaf springs are most generally used in the rear suspension hardware. Leaf springs are made by the curving of flat steel bands. It is formed with the tying of a couple of thin leafs with short ones and then the longer ones put on top of one another. With this tying method, it does not break and is forced to be flexible. Every curve of the leaf is called a bend and this bend intensifies from the longer leaf to the shorter leaf. With the curving of the edge of the longest spring a spring eye is formed.

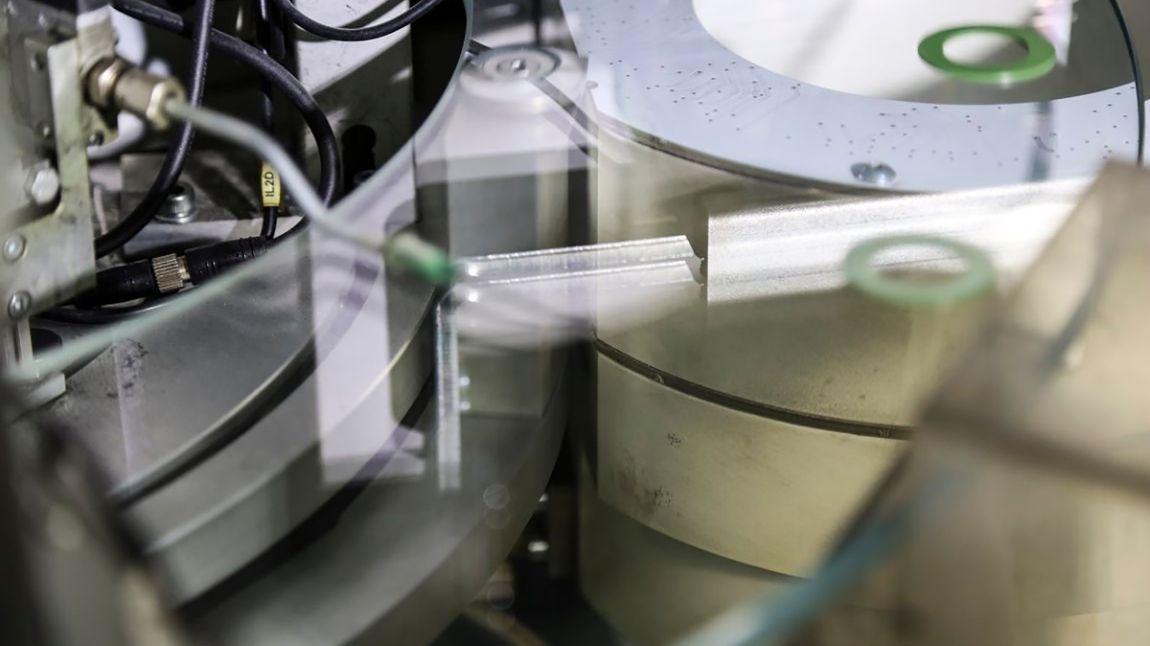

Through this part the spring is hung with a screw. Rubber rings are placed between the screw and its niche within the hanger. Thus, the metal does not touch the other metal. These rubber rings absorb the vibrations and they prevent their transmission into the chassis. Meanwhile, while the spring is bent, the eye of the spring can bend forward and backward.

Cardan Shaft Hanger

An intermediate element is needed for the transfer of the motion received from the exit mills of the transmission into the differential and into the wheels through the differential. This element is the cardan mills. Cardan mills are made up of high quality steel and they are supported with rubber mounting dampers against bending vibrations. The hanger mounts developed by Angst Pfister Advanced Technical Solutions eliminate the vibrations occurring during the force transfer and help the proper functioning of cardan mills.

An intermediate element is needed for the transfer of the motion received from the exit mills of the transmission into the differential and into the wheels through the differential. This element is the cardan mills. Cardan mills are made up of high quality steel and they are supported with rubber mounting dampers against bending vibrations. The hanger mounts developed by Angst Pfister Advanced Technical Solutions eliminate the vibrations occurring during the force transfer and help the proper functioning of cardan mills.

Rubber Bolster

Rubber bolsters are designed as suspension springs that can press on the high axis with force, absorb the angular and slipping forces and do not require maintenance.

This system that is formed with the combination of the rubber with metal parts with special geometrical shapes, is made up of high strength steel and rubber materials, especially against the very high impacts and corroding effects during heavy working conditions. Thus, they have the strength and flexibility to perform for a long time during heavy working conditions.

Rubber to Metal Bushings

These products with high carriage capacity work harmoniously without the need of greasing and without any sign of corroding against the angular motions and distortions on any platform. The rubber vulcanized products with ramming materials mounted on the tie rods in heavy vehicles are required in hydraulic damper connections and the mills bearing of other heavy load machinery.

Other Rubber-Metal Parts

For making the heavy vehicles safer and more comfortable Angst Pfister Advanced Technical Solutions carries out the design and manufacturing of rubber metal parts for truck and trailer manufacturers. Angst Pfister Advanced Technical Solutions continues with its operations as the solution partner of the main industry in line with the needs of its customers and also develops all processes from prototype phase into serial production within its own structure and with its expert engineers.