Published by Angst+Pfister on February 2021

When young engineers dream of space, Angst+Pfister is happy to make the dream a reality – with lots of down-to-earth technical experience for their special requirements. Students of the Swiss ARIS Space and Rocket Project looked to Angst+Pfister for seals in their bid to win an international rocket competition.

An ambitious team of students from the ETHZ Swiss Federal Institute of Technology in Zurich is reaching for the stars – following in the footsteps of Switzerland’s internationally-renowned education establishments, which have produced no less than 21 Nobel Prize winners. The students plan to launch a hybrid rocket in a far off place where the air is very thin.

A step at a time into the stratosphere

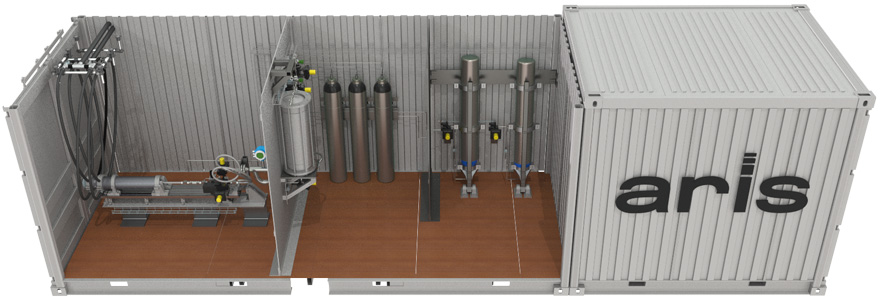

ARIS stands for Akademische Raumfahrt Initiative Schweiz. It was founded in 2017 by students from the ETHZ and incorporates the neighbouring science universities of Zurich and Luzern, while also being closely linked with the innovative industry of Switzerland. The students see space as a future enterprise and business sector. Their initiative aims to inspire the next generation, for whom space should be more than just a dream. By 2029, ARIS would like to have reached orbit – and are putting this plan into action step by step. The next stage for the students is to win the Spaceport America Cup in New Mexico, initially in the 30,000 ft category – in which the rocket has to reach as near as possible the exact height of 30,000 ft, that is about 9,100 metres.

The concomitant Euler 2020 project is a homage to the Swiss mathematician Leonhard Euler, one of the most brilliant brains of the 18th century. As part of this project, the height of 30,000 feet will be attained first off using a commercial engine. Simultaneously, another student team will be working on another project, the Iride 2020, to design and test their own engine. A further team of students will then build the engine into the rocket during 2021 and attempt a first flight. The students are not exactly lacking in ambition.

A shared passion for technology

Angst+Pfister products have already been used in an earlier ARIS project. “The seals are incredibly important for the engine,” says ETHZ student Julius Wymann. “If they do not work, the result can be a loss of power and system damage. For this reason, we needed specialist and professional knowhow that extends beyond classic sealing solutions, and so once again we knocked at the door of Angst+Pfister.” There they found Yves Riedo, Senior Engineer in Sealing Technology who was instantly impressed by the energy of the team of students. Julius Wymann explains: “Engines hold a strong fascination for us; we all share the same passion.” The interaction of power, control and elegance is captivating.

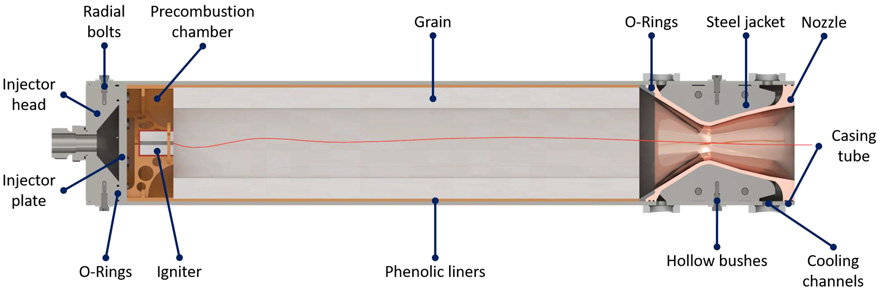

But when it came to the seals, the students were in less familiar territory. “Finding the exact dimensions is a science in itself,” explains Julius Wymann. They primarily experienced difficulties with the design of the seal for the nozzles. These are made of copper that expands significantly in high temperatures. “A sealing point for O-rings looks easy,” says Yves Riedo. However, room constraints, the exact pressure on the O-rings and the changing physical state of the media make for a more complex situation as materials expand at different rates. “The design of the groove - the slot for the O-ring – and the choice of material require depth of knowledge and experience.”

Materials for top performance

The students also needed special materials that are able to withstand extreme stress. Yves Riedo reached deep into the vaults: “One of the materials we used was Kalrez® with a selling price of several thousand euros per kilogramme.” The material allowed the students to carry out the maximum number of tests – without having to replace the seals and dismantle the engine every time. “If you want to win, you have to be better than the competition,” says Yves Riedo with a twinkle in his eye. The engine required a complete sealing system of 17 O-rings in six different dimensions, and a combination of five different materials. There had to be seals between the injector and combustion chamber, the combustion chamber and outlet nozzle, for the cooling system within the nozzle with the connections to the casing and the plenum chamber, as well as for diverse sensors within the injector (see illustration). In addition to the Kalrez® (FFKM) already mentioned, an ethylene propylene diene monomer elastomer (EPDM), a fluoroelastomer (FKM) and a fluoroelastomer (FKM) with a seamless FEP lining (FEP-O-SEAL®) were used.

The engine will be filled with an explosive oxidising agent that is warmed to reach a pressure of around seventy bar. In operation minus temperatures are encountered briefly in the injector and also temperatures up to +2800 degrees in the combustion chamber. Consequently, the sealing system will be confronted with conditions of extreme chemical and thermal stress and needs to function reliably several times. “We use nitrous oxide as the oxidising agent combusted with sorbitol. It also contains paraffin and aluminium,” says the ETHZ student. “The special material that we selected to use gives us a clean seal on the copper outlet nozzles no matter how high the temperatures or size of expansion gap. The seals on the injector, meanwhile, fulfil the requirements of nitrous oxide fully.” With New Mexico clearly in sight: It’s not going to be a matter of the materials.

Kalrez® is a DuPont™ brand. DuPont™, the DuPont Oval Logo, and all trademarks and service marks denoted with ™ or ® are owned by affiliates of DuPont de Nemours, Inc.

Engine cross-section

On the left is the injector plate for the liquid oxidising agent that on injection is atomised and vapourised. The injector has to remain sealed for both physical states. The oxidising agent then reacts with the gradually vapourising fuel (grain) in the combustion chamber. Pressure is generated by combustion of the gas mixture, which is transformed into kinetic energy by means of the copper Laval nozzles. And in accordance with the rocket principle produces the thrust of the engine.

The engine will be filled with an explosive oxidising agent that is warmed to reach a pressure of around seventy bar. In operation minus temperatures are encountered briefly in the injector and also temperatures up to +2800 degrees in the combustion chamber. Consequently, the sealing system will be confronted with conditions of extreme chemical and thermal stress and needs to function reliably several times. “We use nitrous oxide as the oxidising agent combusted with sorbitol. It also contains paraffin and aluminium,” says the ETHZ student. “The special material that we selected to use gives us a clean seal on the copper outlet nozzles no matter how high the temperatures or size of expansion gap. The seals on the injector, meanwhile, fulfil the requirements of nitrous oxide fully.” With New Mexico clearly in sight: It’s not going to be a matter of the materials...

Conclusion

The journey to space is fraught with complexities, from the precise engineering of rocket engines to the unforgiving environment of the cosmos. Yet, through collaboration and shared passion, the team has navigated these challenges with determination and ingenuity. The ARIS project represents not only a quest for scientific advancement but also an opportunity to inspire future generations and redefine the boundaries of what is possible.

As the team sets its sights on the Spaceport America Cup in New Mexico and beyond, the partnership between Angst+Pfister and the ETHZ students serves as a beacon of innovation and cooperation in the pursuit of exploration. Together, they are proving that with dedication, expertise, and a shared vision, even the stars are within reach.

Get connected!

Let’s talk about your challenges and how Angst+Pfister can support you.

Discover Your Path to Innovation

Get to know our expertise in various fields and and partner with us for customized engineering solutions.