Connect on LinkedIn

Key Facts at One Glance:

In the highly regulated food and beverage industry, using safe plastic components is paramount. As companies strive to meet strict compliance requirements while maintaining economic viability, the challenges can seem overwhelming, especially for medium sized OEMs. However, with the right expertise and approach, it is possible to achieve both safety and cost-effectiveness in the production of plastic components.

Let's talk!Operating in the food and beverage industry means navigating a landscape filled with strict regulations. Compliance with these regulations is not just about ticking boxes; it is essential to avoid severe legal and financial repercussions. However, the complexity of these regulations can be daunting, particularly for companies without specialized knowledge in the field of plastic technology. The expertise required spans multiple disciplines, including material selection, engineering, and production processes, all of which need to align with regulatory standards.

Economic Efficiency Under Pressure

For many companies, particularly medium sized OEMs, the time and cost associated with achieving compliance can be a significant burden. The availability of high-quality materials that meet regulatory standards, coupled with the need for advanced engineering and production know-how, adds to the complexity. The challenge is not just to produce "safe" plastic components but to do so in a way that is economically viable. This involves careful consideration of material costs, production efficiency, and the scalability of solutions.

Mastering the Art of Safe Production

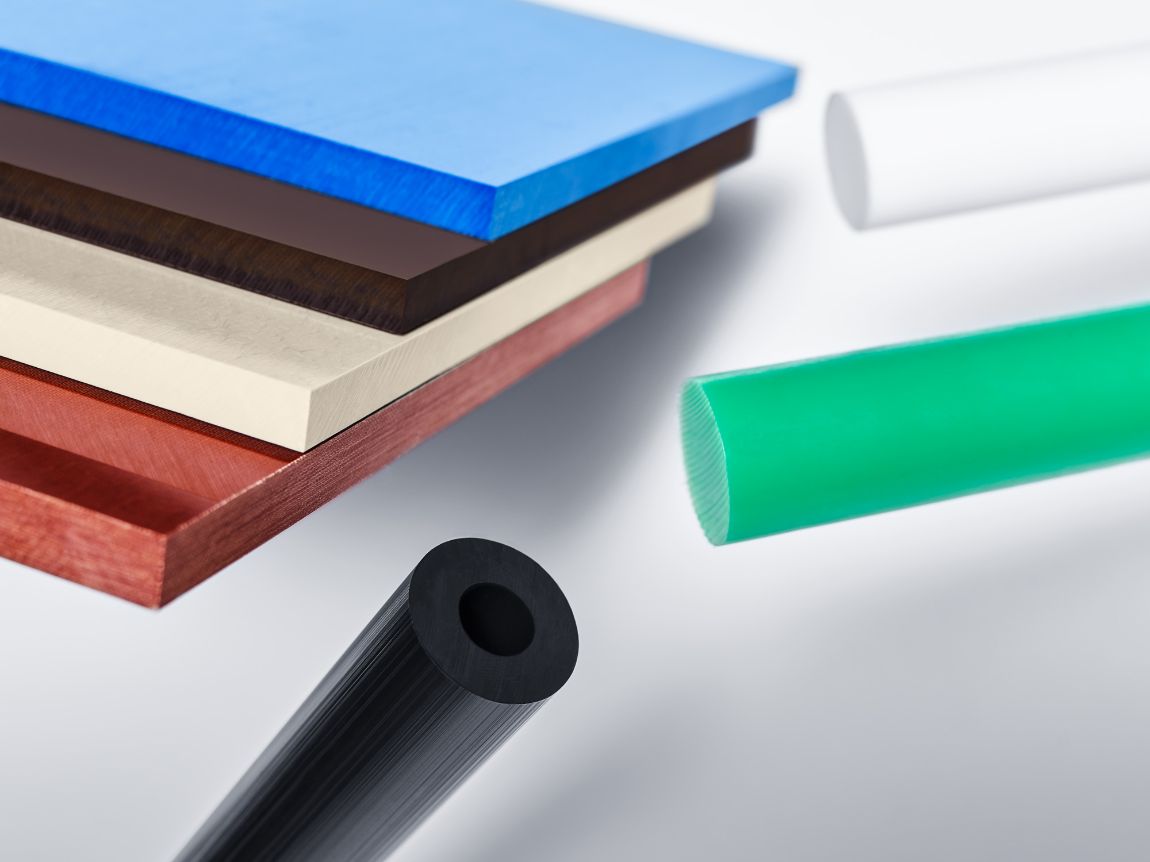

At Angst+Pfister, we understand these challenges and have developed a comprehensive approach to producing plastic components that are both safe and economically feasible. Our expertise lies in the production of complex components made from high-performance, certified plastics such as PEEK, PTFE, POM, PET, PA and PE. These materials are often required in large volumes and must meet specific certification standards, such as those outlined in the EU’s EC 1935/2004 regulation or the FDA (U.S. Food and Drug Administration).

Our process begins with meticulous material selection, ensuring that only certified, high-quality plastics are used. This is followed by rigorous engineering to design components that not only meet compliance standards but are also optimized for production efficiency. Our engineering team brings a wealth of experience, particularly in dealing with complex parts that require advanced manufacturing techniques.

Comprehensive Compliance Support

To further ensure the safety and compliance of our products, we conduct migration tests in collaboration with external laboratories, providing our clients with a Statement of Compliance. This certification is critical for companies needing to demonstrate that their products meet all relevant safety standards.

Moreover, Angst+Pfister offers a GMP (Good Manufacturing Practice) certified process, which, while not always mandatory, serves as a hallmark of quality and safety in production. Our commitment to GMP underscores our dedication to producing plastic components that are not only compliant but also of the highest quality.

From Concept to Compliance

Our involvement doesn’t end with production. We provide end-to-end support throughout the entire process - from the initial design phase through to the final compliance checks. This holistic approach ensures that our clients receive components that are tailored to their specific needs, whether they are looking for innovative design solutions or seeking to optimize production for cost efficiency.

In today’s food and beverage industry, the stakes are high when it comes to the safety of plastic components. However, with the right expertise, it is possible to navigate the complex regulatory environment and produce components that are both safe and economically viable. At Angst+Pfister, we combine our deep knowledge of plastic technology with a commitment to quality and compliance, delivering solutions that meet the highest standards of safety and efficiency.

Let’s Talk about Your Project!

Request a Free Consultation and Find a Perfect Solution Customized for you.

Based on our assortment we create and develop an individual solution for your application – or we even develop from scratch a high-performance part for your product to ensure quality & safety. For expert advice and customized solutions tailored to your specific needs,

Let's talk!

Related Pages and Downloads

At Angst+Pfister, we stay ahead of the curve in Engineering Plastics Technology. We offer a comprehensive range of services for practically every applica ...

Get connected!

Let’s talk about your challenges and how Angst+Pfister can support you.

Your one-stop shop for industrial components

Dive into the extensive range of standard applications in the online shop of APSOparts with great benefits for efficient order processes!